QDX-100 Automatic paper splicing machine

JIANGYINQIDA PACKAGING MACHINERY CO., LTD

We focus on designing each machine and each component, to the customer's specific specifications, in a customized and cost-effective manner. Our employees are all company employees with 20 years of experience. They are helping customers find and choose the right solutions and production lines every day.

Key words:

single face automatic corrugating machine | corrugated roller | corrugated board assembly line

Classification:

Product Description

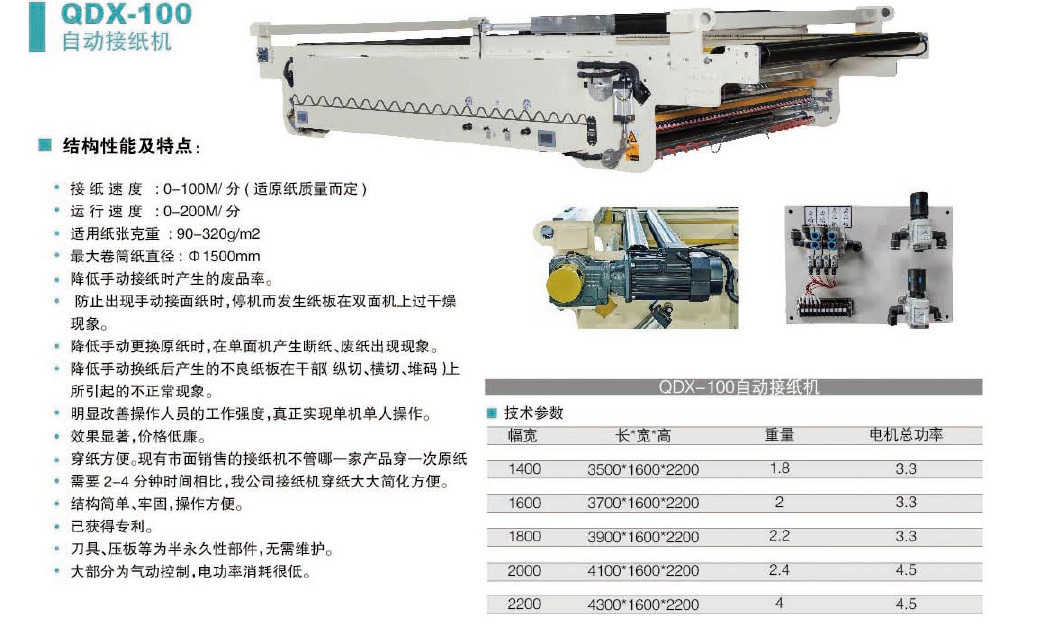

X-100经济型自动接纸机介绍

纸箱行业已进入薄利时代,纸箱成本中原纸材料所占的比重又大,所以节省原纸与纸箱制造企业的效益息息相关。作为瓦线上能明显带来节约原纸效果的接纸机越来越被纸箱制造企业所接受。

目前国产瓦线平均速度为60-120米/分钟,但是市面上销售的自动接纸机接纸速度一般达到150-250米/分钟,并且价格昂贵。中低档瓦线上安装此类接纸机显然不经济。

针对这种情况,我公司研制出接纸速度为0-100米/分钟,正常生产速度能达到0-200米/分钟并且性能稳定价格低廉的经济型自动接纸机,能满足中低档瓦线的生产需求。

下面向您详细介绍X-100经济型自动接纸机的具体性能与参数。

1、给您带来立竿见影的投资回报

*具体效果分析参考第3、4页。

*降低手动接纸时产生的原纸消耗。

*降低手动接纸时产生的废品率。

*防止出现手动接面纸时,停机而发生纸板在双面机上过干燥现象。

*降低手动更换原纸时,在单面机产生断纸、废纸出现现象。

*降低手动换纸后产生的不良纸板在干部(纵切、横切、堆码)上所引起的不正常现象。

*明显改善操作人员的工作强度,真正实现单机单人操作。

2、与现有市面销售接纸机的区别

*效果显著,价格低廉。与现有市面销售的接纸机16万-30万/台的价格相比,具有无可比拟的价格优势。

*穿纸方便。现有市面销售的接纸机不管哪一家产品穿一次原纸需要2-4分钟时间相比,我公司接纸机穿纸大大简化方便。

*结构简单、牢固,操作方便。

3、运行费用低廉

*刀具、压板等为半永久性部件,无需维护。

*大部分为气动控制,电功率消耗很低。

机 械 参 数

** 主 要 参 数 **

1). 产 品 型 号: X-100

2). 接 纸 速 度: 0-100M/分(适原纸质量而定)

3). 运 行 速 度: 0-200M/分

4). 适用纸张克重: 90-320g/m2

5). 最大卷筒纸直径: Φ1500mm

6). 机 器 幅 宽: 1600mm-2200mm

7). 双面胶带宽度: 30mm-40mm

8). 接纸成功率: 99%以上

9). 张力控制方式: 手动或自动(自动为选配事项)

10). 机 器 重 量: 约2000kg

11). 机器油漆颜色: 标准颜色或客户指定颜色

This machine consists of three parts: roll paper shaftless support, single-sided corrugated forming machine, and rotary slitting machine. Use roll paper as the paper material, after corrugating, gluing, bonding, drying, and continuous operation and automatically cut into single-faced corrugated cardboard of the required specifications.

After the machine adopts vacuum adsorption, the glue volume is small, the drying is fast, the production speed is accelerated, the degree of automation is high, the power consumption is small, and the efficiency is high, which is suitable for mass production. It is easy to operate and maintain, safe and reliable. It is an ideal equipment for small and medium-sized color printing and carton packaging enterprises.

The upper corrugating roller, pressure roller and middle corrugating roller of this single-sided corrugating machine are pneumatically coupled. The vacuum suction type roller is made of alloy steel (48CrMo) with a roller diameter of 266mm and is processed by grinding.

Technical Parameters

| Paper web | 1320/1650/1800mm |

| Mechanical speed | 0-50m/min |

| heating method | Electric heating (quartz tube), liquefied gas, heat transfer oil, steam |

| Corrugated | UV/A, C, B, D, E or customized |

| power supply | Three-phase four-wire, 380V, 50H z, 4KW speed regulating motor |

This machine is composed of three parts: roll paper shaftless support, single-sided corrugated forming machine, and computer slitting machine. Use roll paper as the paper material, after corrugating, gluing, bonding, drying, and continuous operation and automatically cut into single-faced corrugated cardboard of the required specifications.

The machine adopts thick wallboard and thick rollers, the whole machine is stable and reliable, with high degree of automation, low power consumption, high efficiency, and is suitable for mass production. It is easy to operate and maintain, safe and reliable. It is an ideal equipment for small and medium-sized color printing and carton packaging enterprises.

This single-face corrugator is a heavy-duty guide-claw upper corrugating roller, and the pressure roller and the middle corrugating roller are clutched pneumatically, and the roller diameter is 237mm.

Technical Parameters

| Paper web | 1320mm 1450mm 1650mm |

| Mechanical speed | 0—35M/MIN |

| heating method | Electric heating (quartz tube), liquefied gas, heat transfer oil, steam |

| Corrugated | UV/A,C,B,D,E OR custom made |

| power supply | Three-phase four-wire, 380V, 50Hz, 4Kw speed regulating motor |

D series corrugated host QDWJ-920~1650 type

"Electric steam type corrugator" adopts vacuum adsorption type paper guide, equipped with heat regulation device. The upper and lower corrugations are made of high-quality alloy steel, after special treatment, the hardness is HRC55~58 and the surface is ground and chrome-plated.

Computer cross-cutting machine

This machine adopts frequency conversion speed regulation, step feeding, computer control, simple operation, reliable performance and precise cutting.

Model: 1320/1450/1650/1800

Accuracy: ±1mm

Speed: 0-50m/min

The slitting is two-way slitting, and various specifications of corrugated cardboard or ordinary cardboard can be adjusted arbitrarily according to needs

Related Products

Welcome your message consultation

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:+86-13901527161